Building large structural composite components for the maritime industry

At Qconcepts Design & Engineering, we specialize in the development and manufacturing of large-scale, structural composite components for the maritime industry.

Our approach is driven by client-specific requirements, focusing on custom designs and structural properties. Each project begins with a detailed assessment, ensuring that the design and engineering phases meet both structural and financial expectations.

Step 1: precision measurements with 3D scanning technology

A typical project begins with an existing structure or “void” within a vessel. Using cutting-edge 3D scanning technology, we capture every detail of the area, creating a highly accurate digital baseline model. This process identifies real-world deviations from theoretical designs, ensuring even the smallest irregularities in the ship’s surfaces are accounted for. The resulting model is shared with the client for approval, providing a solid foundation for the engineering and design phases to follow.

Step 2: engineering and material selection

Once the baseline design is confirmed, our engineering team performs a detailed analysis to determine the optimal material, thickness, and allowable deflections. all while balancing cost considerations and taking in account class compliance when required. Here, we make crucial decisions about the production method, choosing between advanced infusion techniques or the precision of a prepreg system. This ensures the final composite components are perfectly suited to withstand the demanding conditions of marine environments.

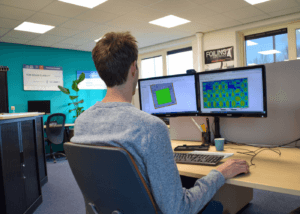

Step 3: from model to manufacturing

With the engineering model finalized, we develop detailed manufacturing drawings, production instructions, and CNC programs to drive an efficient production process.

Our in-house manufacturing facility enables close collaboration between engineering, production planning, and on-the-ground operations, ensuring agility and precision at every step. Regular client meetings allow us to integrate any late-stage adjustments to measurements or details, ensuring that the final component meets clients’ requirements. The installation of secondary parts (e.g. plumbing or electronics) and surface finishing can be taken care of by Qconcepts.

Step 4: delivery and onboard installation

Once production is complete, we manage the logistics of delivering the component to the client. If required, our team also provides on-site installation services, ensuring seamless integration into the vessel. This end-to-end approach guarantees a flawless transition from design and manufacturing to final implementation, prioritizing quality and client satisfaction every step of the way.